Plastic packaging is packaging made of plastic materials and used to protect, transport, store and distribute products. Plastic packaging; It is a light, durable and low-cost material, so it is widely used. However, there is a risk of harming the environment during the disposal of plastic packaging. Meanwhile, Petek Plastik is on the side of nature with eco-friendly plastic packaging!

Plastics are substances formed by transforming some organic and inorganic elements in nature into polymers with a more complex structure under a certain temperature and pressure. Plastic containers, on the other hand, are tools that allow us to store and preserve certain substances using plastic. The meaning of the word plastic is "soft" and "easily shaped"

After plastic wastes are received into the facility, they are classified according to their type (PE, PP, PVC, HDPE, LDPE, PET, PS, etc.). After the separated plastics are washed, they are cut into small pieces and dried in special machines. After this process, plastic wastes are melted, the melted wastes are passed through plastic filters, cut and sized and turned into granules (plastic raw material).

There are many reasons why plastic is so widely used as plastic packaging and plastic bottles in many industries. If we list the properties of plastic material:

Some of the most important features of plastic packaging are:

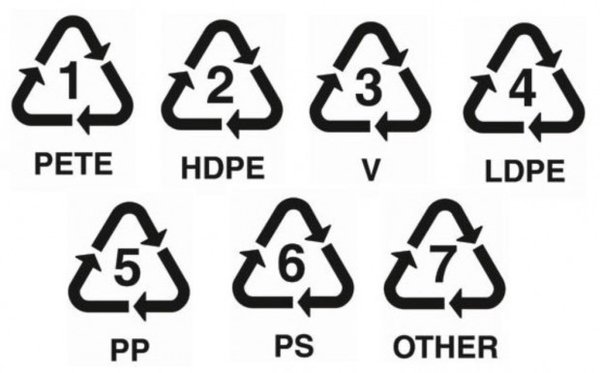

There are some numbers on plastic packages. These numbers and what they mean are explained below.

| CODE | Name | EXPLANATION OF THE NUMBERS ON THE PLASTIC PACKAGING |

|---|---|---|

| 1 |

PET / PETE |

PET stands for polyethylene terephthalate. You may see the PET or PETE code on some plastic products. Usually water, soft drinks and two-liter oils are used in these plastic bottles. When you see these numbers, you can understand that the product is suitable for one-time use. It does not leak any harmful substances into the food it contains. |

| 2 | HDPE / HDP | HDPE is the abbreviation of High-Density Polyethylene. These plastic products, known with the code HDP or HDPE, are generally used in the production of detergent, milk, bags, olive oil bottles and toys. |

| 3 | PVC / V | PVC stands for poly vinyl chloride. They are known by the code PVC or 3V. It is one of the softer and more flexible types of plastic. Mostly used areas are food containers, soft materials and toys. |

| 4 | LDPE | They are known by the code LDPE. Its abbreviation is LDPE Low-Density Polyethylene. It is used in dry cleaning, storage containers and garbage bags. LDPE is prohibited from being used in making water bottles. |

| 5 | PP | PP is short for polypropylene. They are known by the code PP. They are known as one of the most reliable types of plastic because they do not contaminate chemicals into the foods they contain. Unlike other plastics, they do not melt when heated, making this type of plastic a good protector. |

| 6 | PS | PS is short for polystyrene. It is known by its code PS. They are used in products such as plastic plates, cups, spoons and food packages. They are generally disposable (food packages, plastic cups, plates, egg cups and spoons), etc. It is used for. |

| 7 | OTHER | It is known by its PC code. Since they are made of mixed polycarbonate materials, they are not suitable for recycling. |

Although it varies depending on the product to be stored, the common point is that they all need to be stored at room temperature, away from sunlight and away from damp places. Paying attention to these situations is very important to protect the plastic packaging and the product inside. Depending on the areas of use, it is very important for food product bottles to be stored in a dry, cool and sun-free place for the product inside. Agricultural product bottles are also subject to these rules, otherwise the effectiveness of the product may decrease. It is important for automobile product bottles to be protected from sunlight. Since personal care bottles, like food product bottles, store products that are important for our health, it is very important for the product to be stored in a dry, cool and dry place, like food product bottles.

Plastic packaging materials are packages made of plastic and used to package products. This type of packaging is usually manufactured in shapes such as bags, boxes, bottles, tubes, and canisters, and is used in the packaging of various products. It is lightweight, durable and costs less than most packaging materials. Environmental pollution should be prevented by choosing environmentally friendly plastic packaging. Unconscious use of plastic packaging materials can have negative effects on the environment. Therefore, nature is protected by recycling and making new packaging. Types of plastic packaging materials include polyethylene, polypropylene, polyvinyl chloride, polystyrene and polyamide.

As Petek Plastik, on this path we set out with the mission of environmentally friendly plastic packaging, we produce the highest quality pesticide bottles, automotive care bottles, personal care bottles, food product bottles, household cleaning bottles, and coex packaging.

Polyethylene packaging has an important place among plastic packaging materials. Polyethylene attracts attention with its lightness and durable structure. This packaging material is effective in protecting products used in many different sectors. One of the biggest advantages of polyethylene packaging is that they are waterproof. Thanks to this feature, they are preferred as a reliable option in the transportation and storage of various liquids. In addition, polyethylene packaging allows products to be transported without damage, thanks to its durable structure. It is also frequently used in the food industry. These packages protect the freshness and hygienic conditions of the food they contain. This ensures that food stays fresh for longer and reliable products are offered to the consumer.